Academic Foundation

Exploring the core research behind our energy storage and grid stabilization technology.

Planetary Prototyping's energy storage system is not just a battery; it is a Closed-Loop Thermodynamic Machine. We integrate a solar thermal steam plant directly with a pseudo-hydro compressed air system, using a shared water buffer to bridge the two.

- The Thermal Heart: A closed-loop water reservoir circulates between the steam condenser and the air system. It captures waste heat, elevating water from 27°C (cooling the air compressor) to 90°C (heating the air expander).

- Pseudo-Hydro Staged Tiers: Instead of fragile mechanical pistons, we use Digital Hydraulics. Water is pumped into vertical pressure vessels, compressing the air 'spring' above it. By using Staged Pressure Tiers—shuffling air between low-cost low-pressure tanks and high-grade high-pressure tanks—we significantly reduce CapEx while maintaining precise pressure control.

- The "No-Release" Cycle: In this closed cycle, the air never leaves the system. It acts as a permanent pneumatic spring, compressing and expanding without venting. This eliminates emissions, ensures silent operation, and maintains maximum system pressure for instant reactivity.

A robust microgrid requires two contradictory traits: the massive inertia of a thermal plant and the split-second reflexes of a battery. Our hybrid design delivers both, allowing them to cover each other's weaknesses.

- Doubling Max Power: By running the steam turbine and the air expander simultaneously during peak demand, the system can output double the baseload capacity.

- Bidirectional Balancing: Steam turbines are slow to ramp up. The compressed air system acts as a fast-response regulator. It can instantly switch from "Generating" (adding power) to "Load" (absorbing excess power) in milliseconds, smoothing out grid frequency while the steam turbine adjusts at its own pace.

- Deep Storage: While batteries fade after hours, our thermal-backed storage can maintain output for days, ensuring resilience even during extended solar downtime.

Our design leverages the "Cheat Code" of thermodynamics: using waste heat to offset compression losses. By recycling the steam turbine's exhaust heat into the expansion cycle, we achieve efficiencies that defy standard mechanical storage limits.

- Thermal Uplift: Standard adiabatic compression loses energy to heat. Our near-isothermal design captures that heat in the water buffer. When combined with the thermal input from the steam cycle, the simulation demonstrates a Round-Trip Efficiency of ~101.5% (Electrical Output vs. Electrical Input + Thermal Reheat).

- Proven Simulation: As detailed in our 2022 thesis, the system was modeled against 4 years of real-world German grid data. The LSTM neural network accurately predicted price spikes, allowing the system to arbitrage volatility and maximize revenue.

- Island Mode Reliability: In disconnected "Island Mode" simulations, a system successfully balanced load and generation, prioritizing reliability over revenue to prevent blackouts.

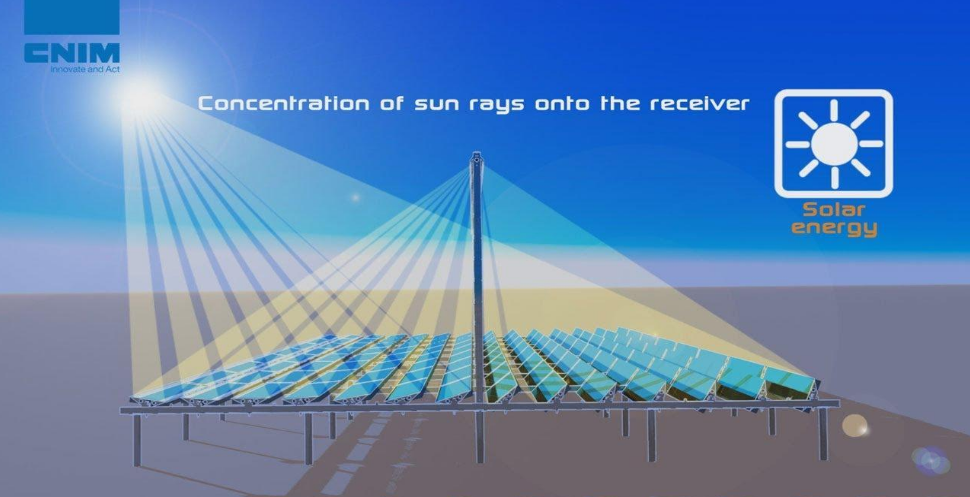

Thermal Generation Modules

The base configuration. Uses Linear Fresnel arrays to gather heat for the steam cycle and thermal buffer. Ideal for high-DNI regions.

The system pairs perfectly with nuclear plants. It utilizes the constant low-grade waste heat for the air cycle and provides "Black Start" capability—using stored air pressure to jumpstart the plant without external grid power.

Any source of medium-grade heat (100°C+) can drive the thermal buffer. This turns constant geothermal wells or factory waste heat into flexible, dispatchable power.

For peak power density, hydrogen-fired turbines can superheat the air expander, achieving maximum thermodynamic efficiency and "green peaker" status.

Storage Modules

The "Digital Hydraulic" piston system. Best for fast response and high cycle life in standard terrestrial environments.

For maximum density, we swap the pressure vessels for cryogenic tanks. Air is cooled to -196°C, shrinking volume by 700x. Ideal for space-constrained urban centers.

We replace steel tanks with the ocean itself. Hydro-static pressure at depth acts as the containment vessel, offering effectively infinite storage volume for offshore wind farms.

Water Heating Applications

Integrates with municipal district heating networks, supplying low-cost thermal energy to residential and commercial buildings.

Provides a reliable source of process heat for manufacturing, food processing, or other industrial applications, offsetting fossil fuel consumption.

The system's waste heat can be used to power multi-effect distillation (MED) or other thermal desalination processes, producing fresh water as a byproduct.

The principles of thermodynamic efficiency and robotic control validated in the ST-CAES thesis were not limited to the power grid. The initial goal was to find a pilot site for the energy storage system, with municipal water treatment plants being a prime candidate due to their high, consistent energy needs.

However, during this feasibility analysis, a more immediate and impactful opportunity was discovered. The energy-intensive oxidation ditches themselves presented a critical optimization challenge. Instead of just powering the existing machinery more efficiently, the core logic of decoupled control and process automation from the ST-CAES research was applied directly to the wastewater process. This pivot led to the development of a novel retrofit design that solves the inherent inefficiencies of the oxidation ditch, creating a new solution entirely.

Continue Exploring

Oxidation Ditch Retrofit

Our flagship optimization solution.

Home

Return to our main page.